Our products and solutions

Standards

Product Categories

- Model no. 1720

- Tests on finished products

- Tests on raw materials

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

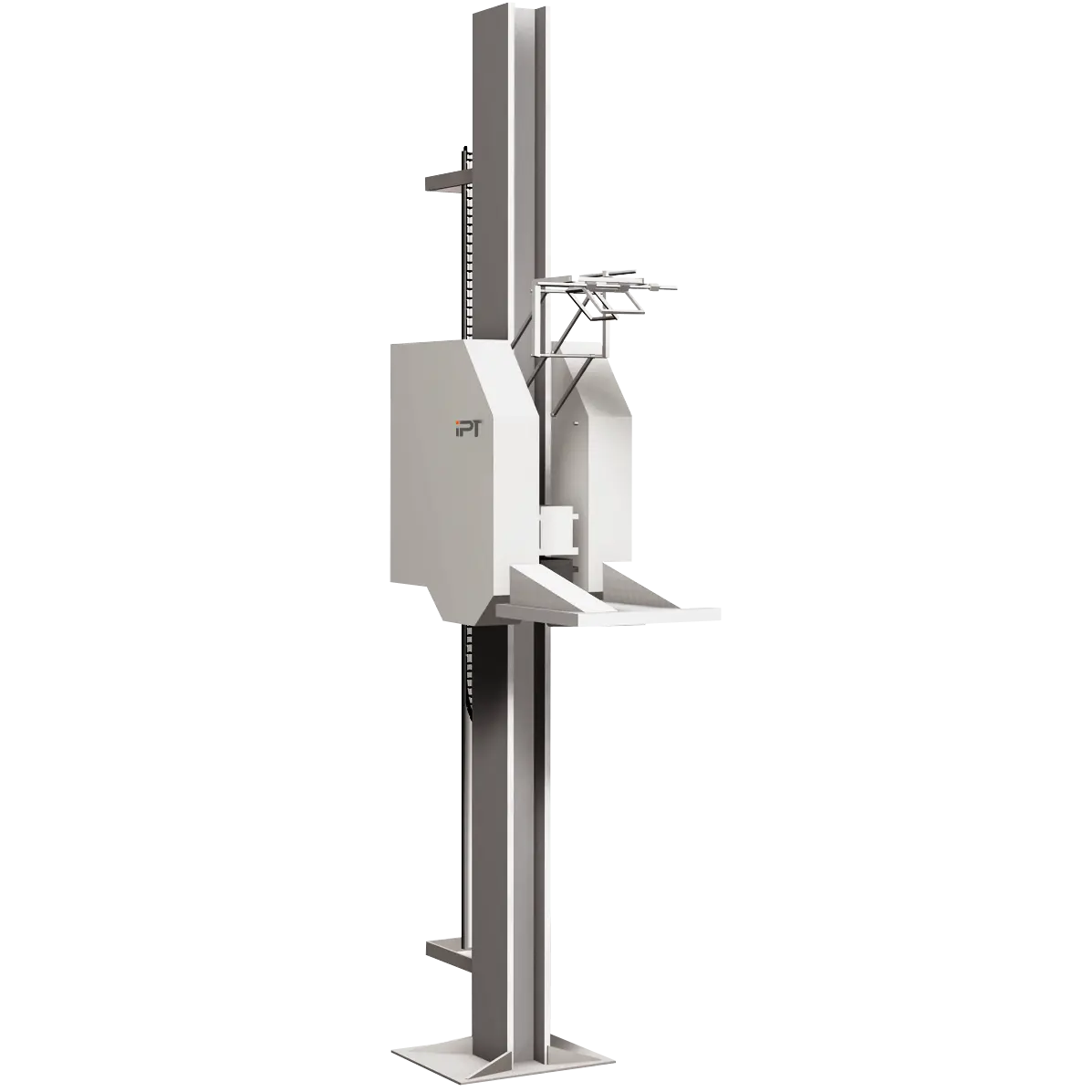

- Model no. 1814

- Tests on finished products

The purpose of this tester is to apply and maintain the correct hydrostatic pressure for internal pressure creep tests.

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

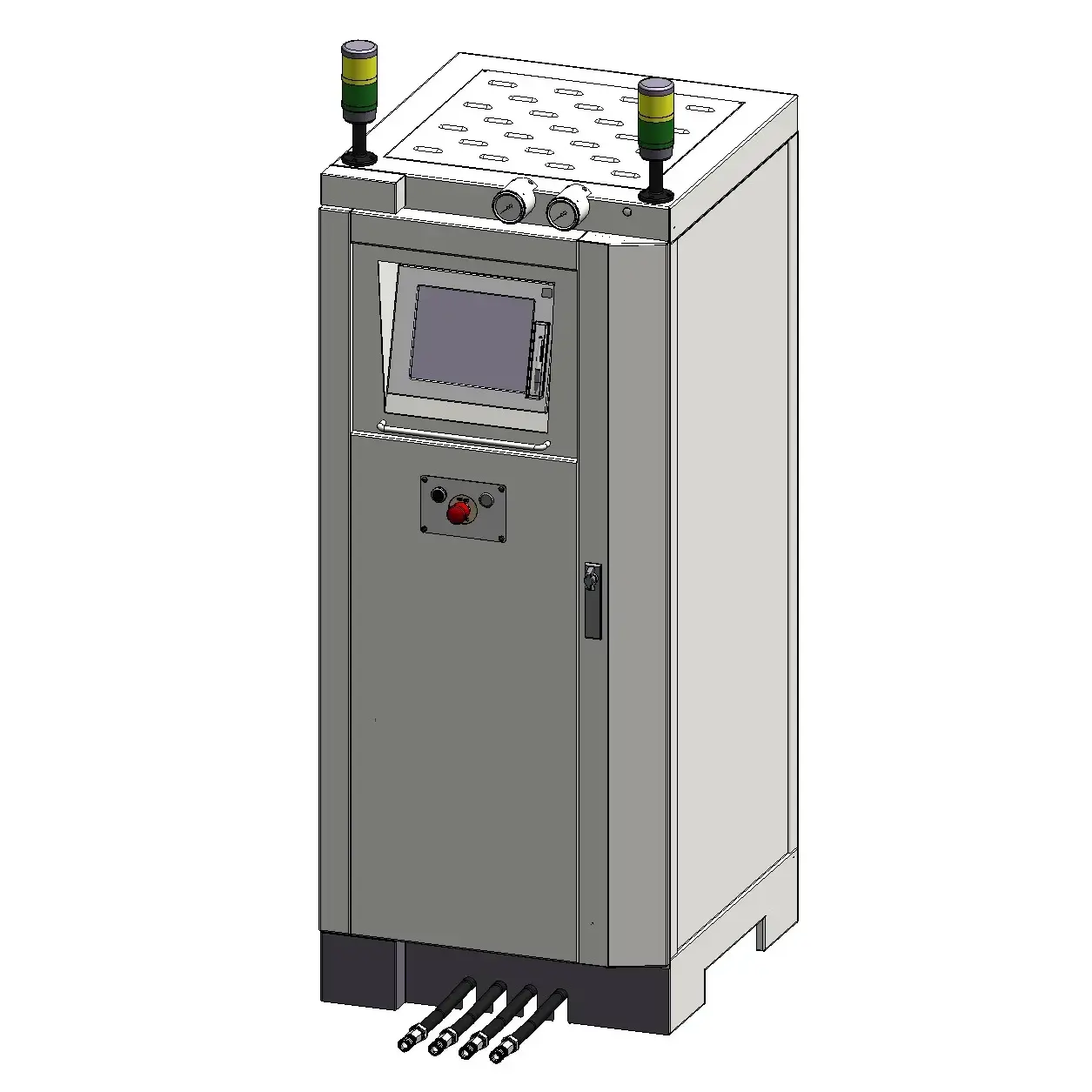

- Model no. 1774

- Tests on finished products

For mid-level testing demands, the Airless Blue Line ensures pressure control at maximum adjustment precision and consistency.

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1790

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

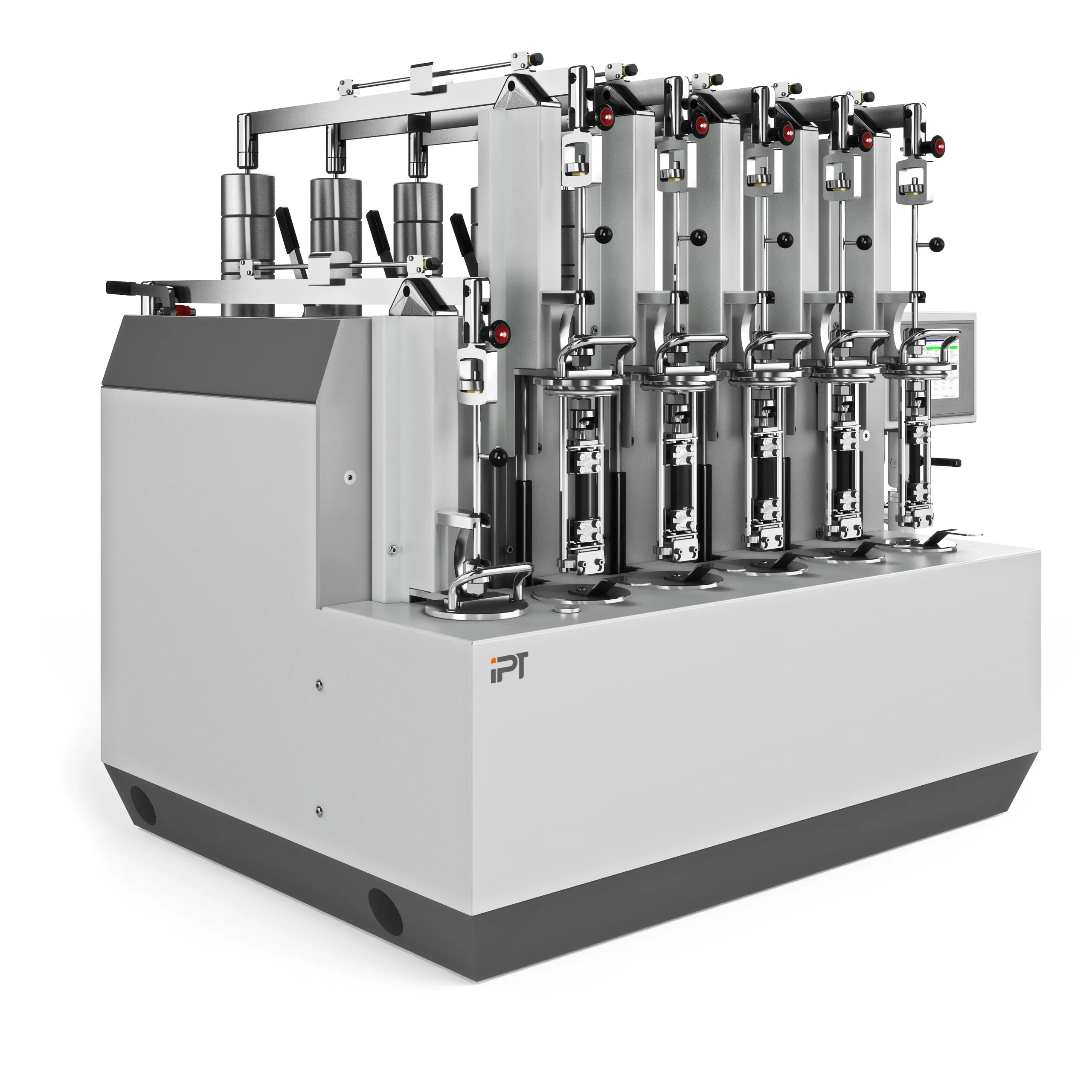

- Model no. 1799

- Tests on finished products

The 1799 full set combines five pressure stations and a test bath in a single housing.

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1718

- Tests on finished products

Standards

- ASTM D 1599

- Model no. 1766

- Tests on finished products

For carrying out dynamic internal pressure tests on pipes and pipe components with sinusoidal or linear pressure curves up to 400 bar.

Standards

- EN 12295

- DVGW W 543

- DVGW W 534

- Model no. 1796/1797

- Tests on finished products

Standards

- ISO 19892

- EN 12295

- DVGW W 543

- Model no. 1830 - 1840

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

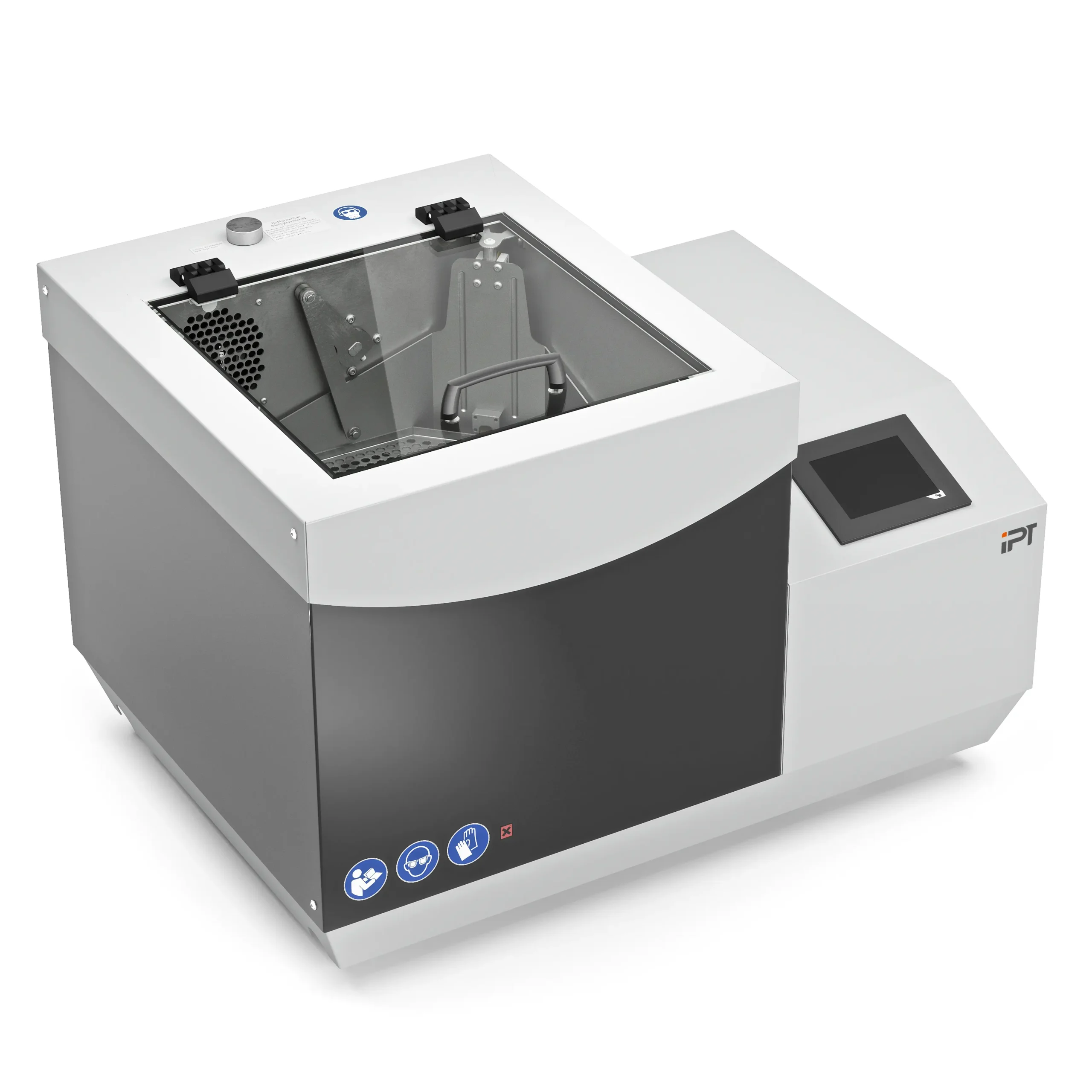

- Model no. 1751 - 1757

- Tests on finished products

The internal pressure creep test is a test procedure for determining the strength of thermoplastic pipes.

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1678

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1810

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1732/1733

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1735/1736

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1685

- Tests on finished products

The internal pressure creep test is a test procedure for determining the strength of thermoplastic pipes when exposed to constant hydrostatic internal pressure at

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1684

- Tests on finished products

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1634

- Tests on finished products

Standards

- ASTM D 1599

- Model no. 1821

- Tests on finished products

Standards

- ISO/CD 19521-1

- ISO/CD 19521-2

- Model no. 1770

- Tests on finished products

The temperature change tester allows you to determine the resistance of connections for pipe systems with rigid or flexible thermoplastic pipes to temperature changing stress.

Standards

- ISO 19893

- DVGW W 534

- DVGW W 543

- DVGW W 542

- Model no. 1663/1669

- Tests on finished products

Standards

- ISO 9967

- ISO 9969

- ISO 13968

- DIN 16961-2

- ASTM D 2412

- Model no. 1771

- Tests on finished products

The combi test stand is used to perform leak tests on pipe connections.

Standards

- ISO 13254

- ISO 13259

- Model no. 1351

- Tests on finished products

The combi test stand 1351 is used to carry out leak tests on waste water pipe systems in the diameter range DN 40 to DN 400.

Standards

- ISO 13254

- ISO 13259

- Model no. 1629

- Tests on finished products

Standards

- ISO 13477

- Model no. 1671

- Tests on finished products

Standards

- ISO 13477

- Model no. 1572

- Tests on finished products

With the increasing popularity of plastic window and door profiles, the demands on the material have also increased in recent years, particularly in terms of load-bearing capacity and durability.

Standards

- EN 477

- RAL GZ 716/1

- Model no. 1713

- Tests on finished products

Standards

- ISO 11173

- ISO 3127

- ASTM D 2444

- Model no. 1523

- Tests on finished products

Standards

- ASTM D 2463

- Model no. 1529/1543

- Tests on finished products

Standards

- ASTM D 2463

- Model no. 1709

- Tests on raw materials

Standards

- ISO 1133

- ASTM D 1238

- Model no. 1398

- Tests on raw materials

Standards stipulate the determination of the carbon black content of polyolefins and/or also the residue on ignition of carbon blacks.

Standards

- ISO 6964

- ASTM D 1895

- Model no. 1598

- Tests on finished products

Standards

- ISO 16770

- Model no. 1727

- Tests on raw materials

Standards

- ISO 16770

- Model no. 1719

- Tests on raw materials

Standards

- ISO 16770

- Model no. 1692

- Tests on raw materials

ASTM D1693 is a test method for determining environmental stress crack resistance (ESCR) in ethylene plastics.

Standards

- ASTM D 1963

- Model no. 1326

- Tests on raw materials

Poor plastic flow properties can cause the flow of material in the funnel of the processing machine to slow down and even stop.

Standards

- ISO 6186

- ASTM D 1895

- Model no. 1132

- Tests on raw materials

The device for determining bulk density is a simple and reliable option for checking the uniform structure of moulding compounds.

Standards

- ISO 60

- ASTM D 1895

- Model no. 1653

- Sample preparation

Standards

- ISO 13479

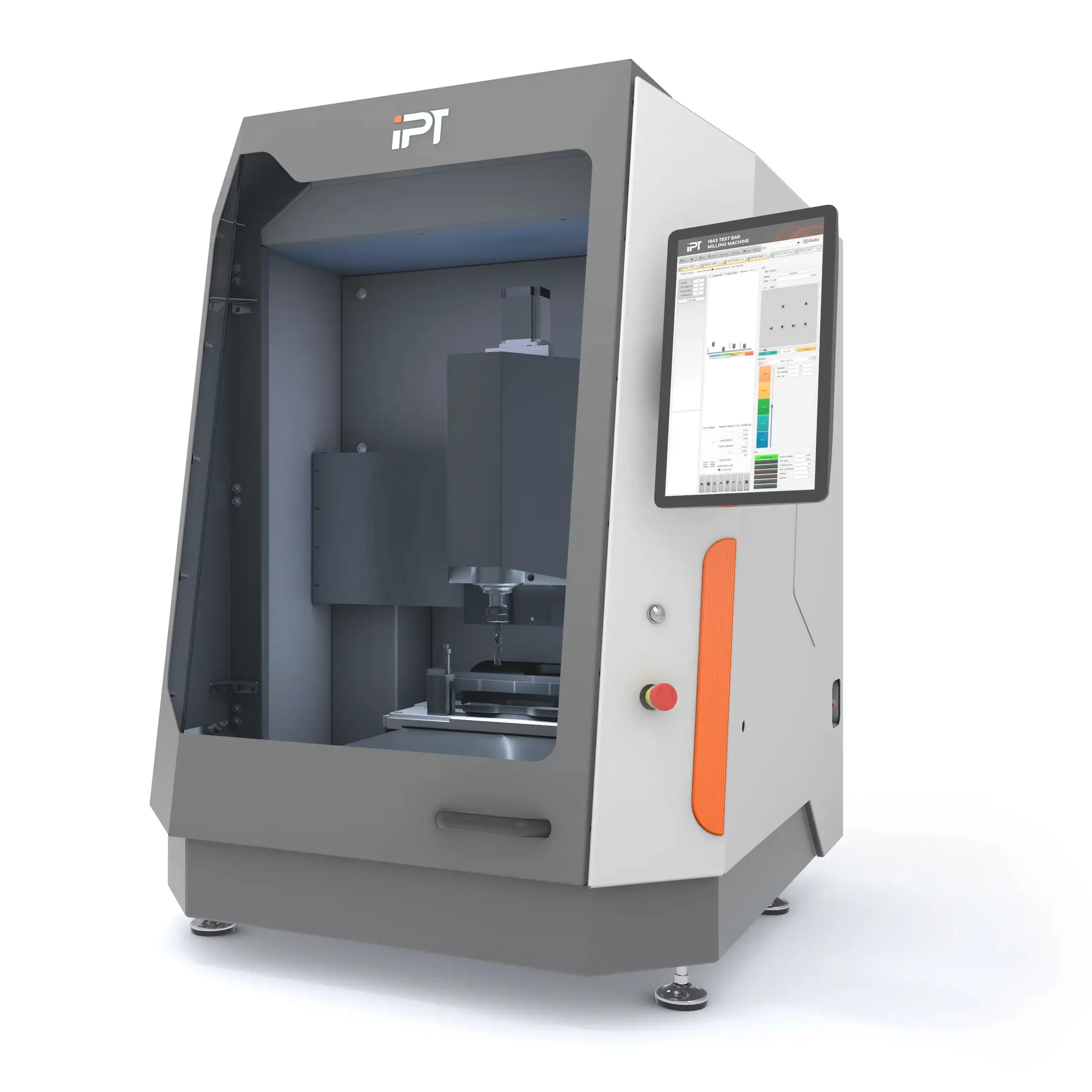

- Model no. 1843

- Sample preparation

Standards

- ISO 527

- ISO 6259

- ASTM D 638

- ISO 179

- ISO 180

- ISO 16770

- ASTM D 1822

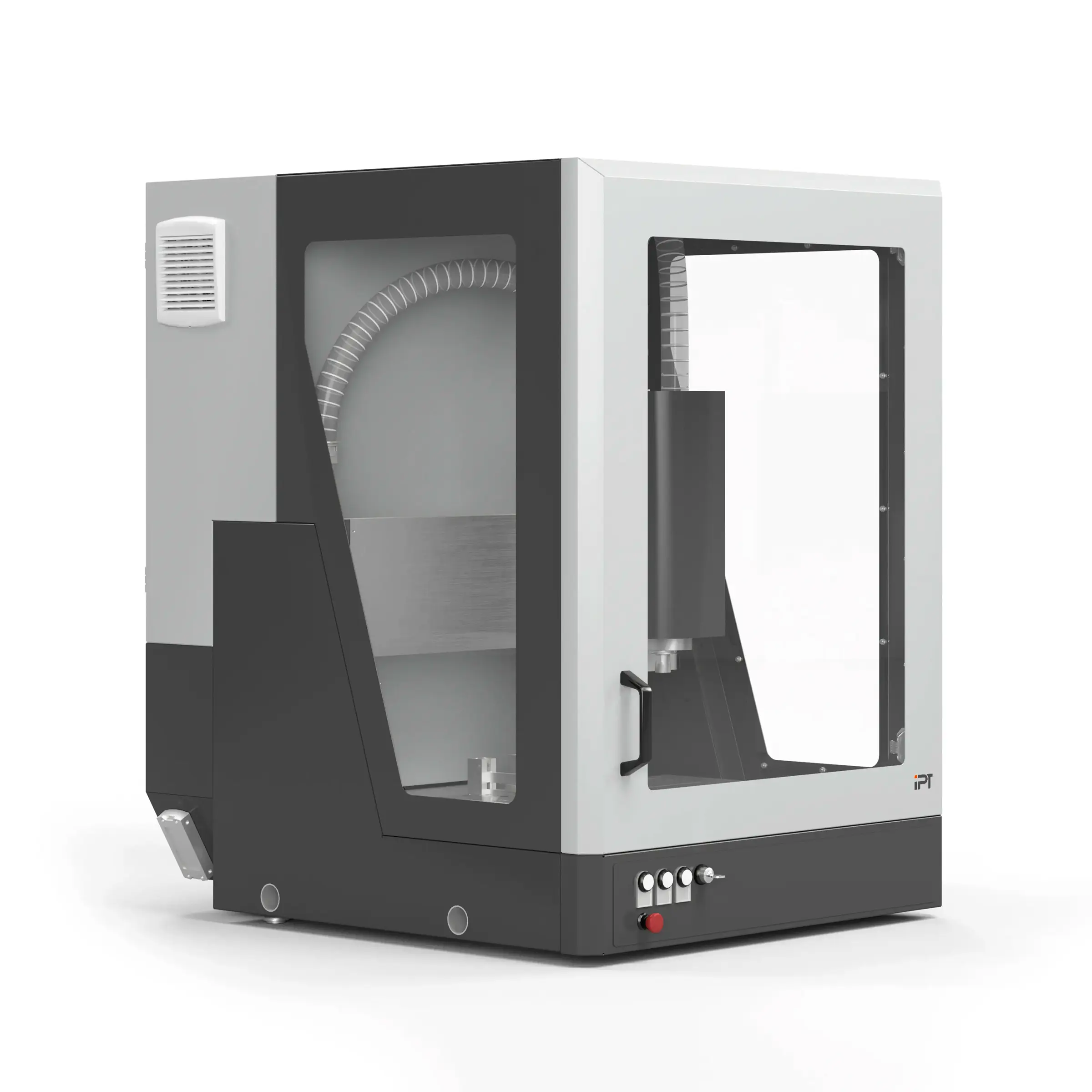

- Model no. 1812

- Sample preparation

Standards

- ISO 527

- ISO 6259

- ASTM D 638

- ISO 179

- ISO 180

- ISO 16770

- ASTM D 1822

- Model no. 1665

- Sample preparation

Standards

- ISO 1133

- ISO 1183

- ASTM D 1505

- Model no. 1808

- Sample preparation

Standards

- ISO 16770

- Model no. 1765

- Tests on finished products

The main field of application for the 1765 series cooling units is to maintain the water temperature in our test tanks at 20°C.

- Model no. 1618

- Tests on finished products

Standards

- ASTM D 1599

- Model no. 1625

- Sample preparation

- Model no. 1411

- Sample preparation

Standards

- ASTM F 1281

- ASTM D 1282

- Model no. 1680

- Sample preparation

Standards

- ISO 13480

- Model no. 1049

- Measuring devices

Standards

- ISO 3126

- Model no. 1623

- Tests on finished products

Standards

- ASTM D 1599

- Model no. 1772

- Tests on finished products

The load box is an extension of the temperature cycling tester for waste water.

Standards

- ISO 13260

- Model no. 1800

- Tests on finished products

Standards

- ISO 9852

- EN 580

- Model no. 1656

- Tests on finished products

Standards

- UNI 9349

- Model no. 1763

- Tests on finished products

Standards

- ISO 11173

- ISO 3127

- ASTM D 2444

- EN 477

- Model no. 1679

- Tests on finished products

Standards

- ISO 17455

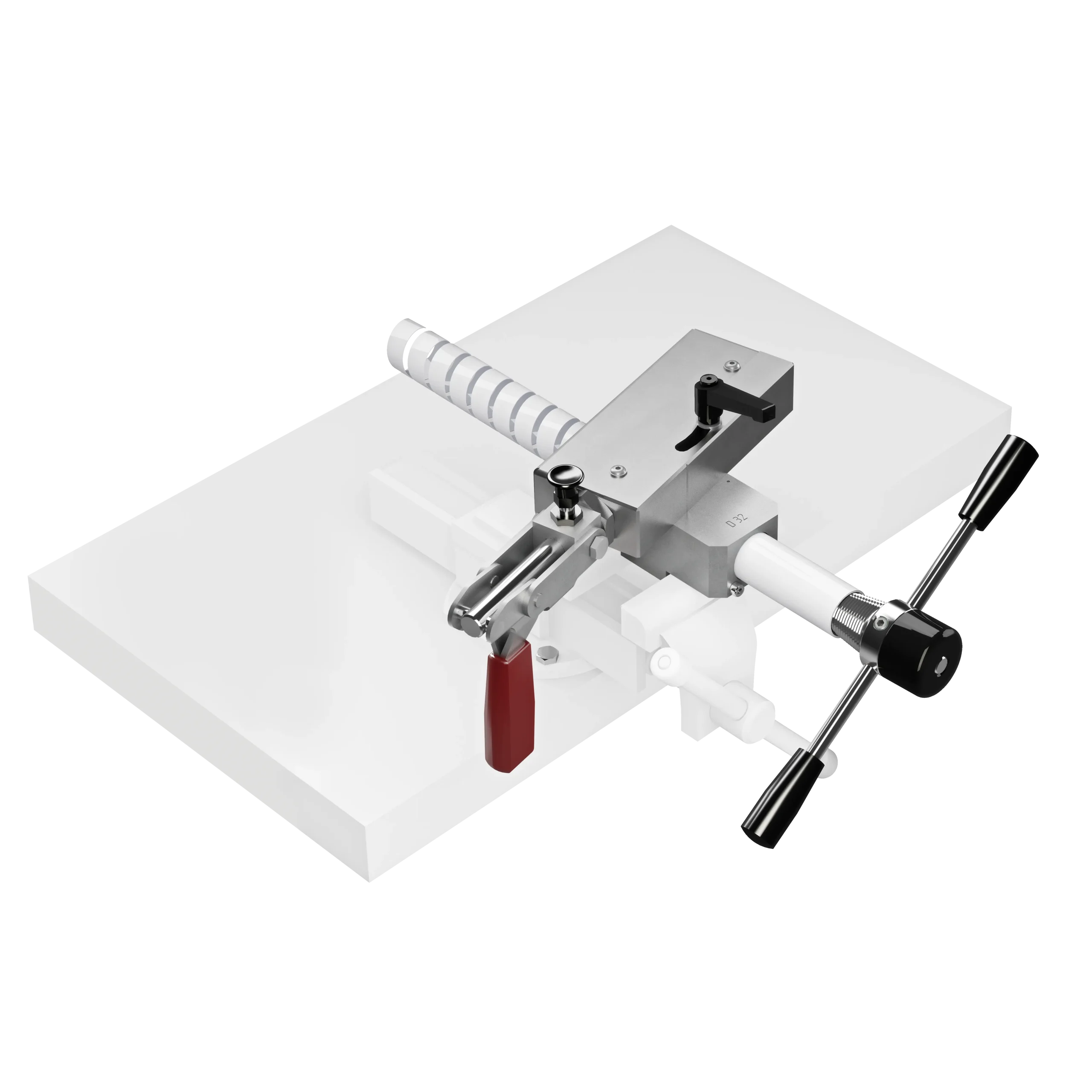

- Model no. 1280

- Tests on finished products

Model 1280 heating pipe closures are used to close underfloor heating pipes, even at high test temperatures of up to 130°C.

Standards

- ISO 1167

- ASTM D 1598

- ASTM D 1599

- Model no. 1654

- Tests on finished products

Standards

- ASTM D 2463

- Model no. 1291

- Sample preparation

To determine the change in length as a result of warm storage, the marking gauge can be used to mark precise parallel circles on the outer surface of pipe segments with a diameter of up to 400 mm.

Standards

- ISO 2505

- NFT 54-047

- Model no. 1268

- Tests on finished products

This test determines the resistance of pipe system connections to thermal cycling

Standards

- EN 1055

- Model no. H3000

- Sample preparation

The analytical balance is required in every test laboratory. It is used to precisely determine important values such as MFR, carbon black content, K-value, degree of crosslinking, OIT, volatile components, water absorption and similar.

- Model no. H3001

- Tests on raw materials

The digital laboratory sieving machine allows you to easilyand accurately determine the fineness and particle size distribution of all dust-like, powdery or granular products.

Standards

- ISO 2395

- ISO 3310

- ISO 565

- DIN 66165

- ASTM D 1921

- ASTM E 11

- Model no. H3002

- Tests on raw materials

This tester is used to determine the density of plastics according to the buoyancy method. The complete set consists of a beaker, thermometer, glass plummet for determining the liquid density, submerged filter and submerged contactor.

Standards

- ISO 1183

- ASTM D 792

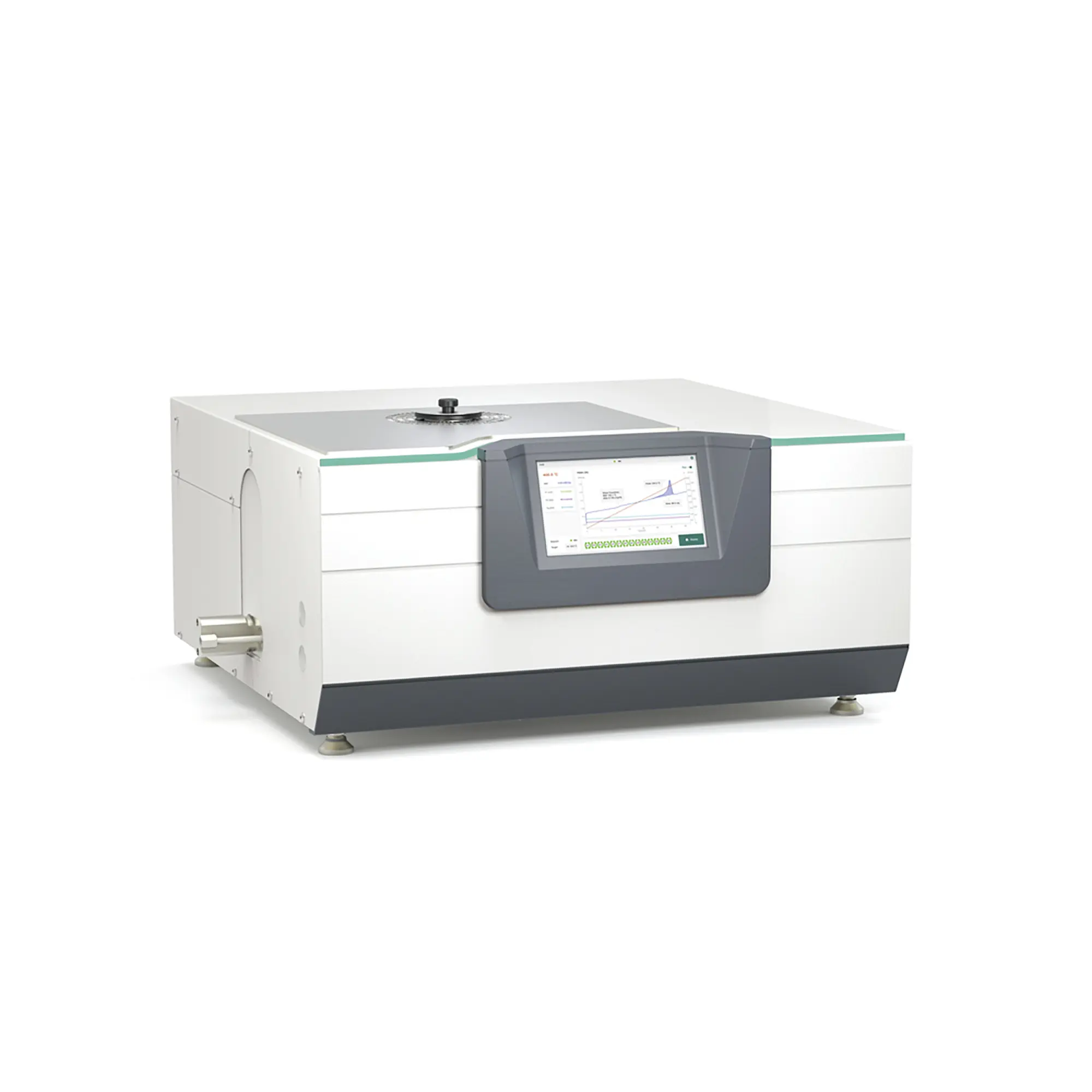

- Model no. H3003-0037/H3003-0038

- Tests on raw materials

Dynamic differential calorimeter for determining the oxidation induction time for plastic piping and protective pipe systems, as well as fittings made of polyolefins.

Standards

- ISO 11357-6

- Model no. H3003-0056

- Tests on raw materials

The device operates according to the heat flow principle. In this method, a sample and a reference are subjected to a controlled temperature programme (heating, cooling or isothermal).

Standards

- ISO 11357-6

- DIN 51007

- ASTM D 3418

- ASTM D 3895

- ASTM E 793

- Model no. H3004

- Tests on raw materials

Standards

- EN 12099

- Model no. H3006

- Tests on raw materials

ISO 10147 stipulates that test samples made from crosslinked polyethylene (PE-X) must be stored in a specified, boiling solvent for a specific period of time and that the percent by weight of insoluble material is then measured.

Standards

- ISO 10147

- ASTM D 2765 Method B

- DIN 16892

- Model no. H3008

- Tests on raw materials

Standards

- ISO 1628-2

- Model no. H3009

- Sample preparation

The microtome is used to cut very thin slices from a sample material in order to subsequently assess the degree of pigment and carbon black dispersion in polyolefin pipes and fittings.

Standards

- ISO 18553

- ASTM D 5596

- Model no. H3013

- Tests on finished products

Standards

- ISO 2507

- ISO 306

- ISO 75

- ASTM D 1525

- ASTM D 648

- Model no. H3014-0013

- Sample preparation

The circulating air oven is used to condition specimens according to the dimensional change of pipes and also as a drying oven (e.g. for determining the degree of crosslinking, water absorption, etc.).

Standards

- ISO 2505

- Model no. H3016

- Tests on finished products

The universal tensile tester is used for performing tension, pressure or bending tests. The classic application is the tensile test. This involves subjecting a sample to an increasing tensile load until it breaks.

Standards

- ISO 6259

- ASTM D 638

- Model no. H3017

- Measuring devices

Circometers are the easiest way to determine the outside diameter of pipes ranging from 15 to 3100 mm.

Standards

- ISO 3126

- ASTM D 2122

- Model no. H3018

- Tests on finished products

The pendulum impact tester enables testing across the entire spectrum of plastic impact testing, Charpy, Izod, impact and Dynstat in accordance with ISO and ASTM standards.

Standards

- ISO 179

- ISO 180

- ISO 8256-A

- ASTM D 256

- ASTM D 4812

- ASTM D 6110

- DIN 53435

- Model no. H3019

- Measuring devices

The outside caliper enables the wall thickness of pipes and fittings to be measured quickly and easily. With the help of the inside caliper, an internal three-point measurement can be carried out quickly and easily.

Standards

- ISO 3126

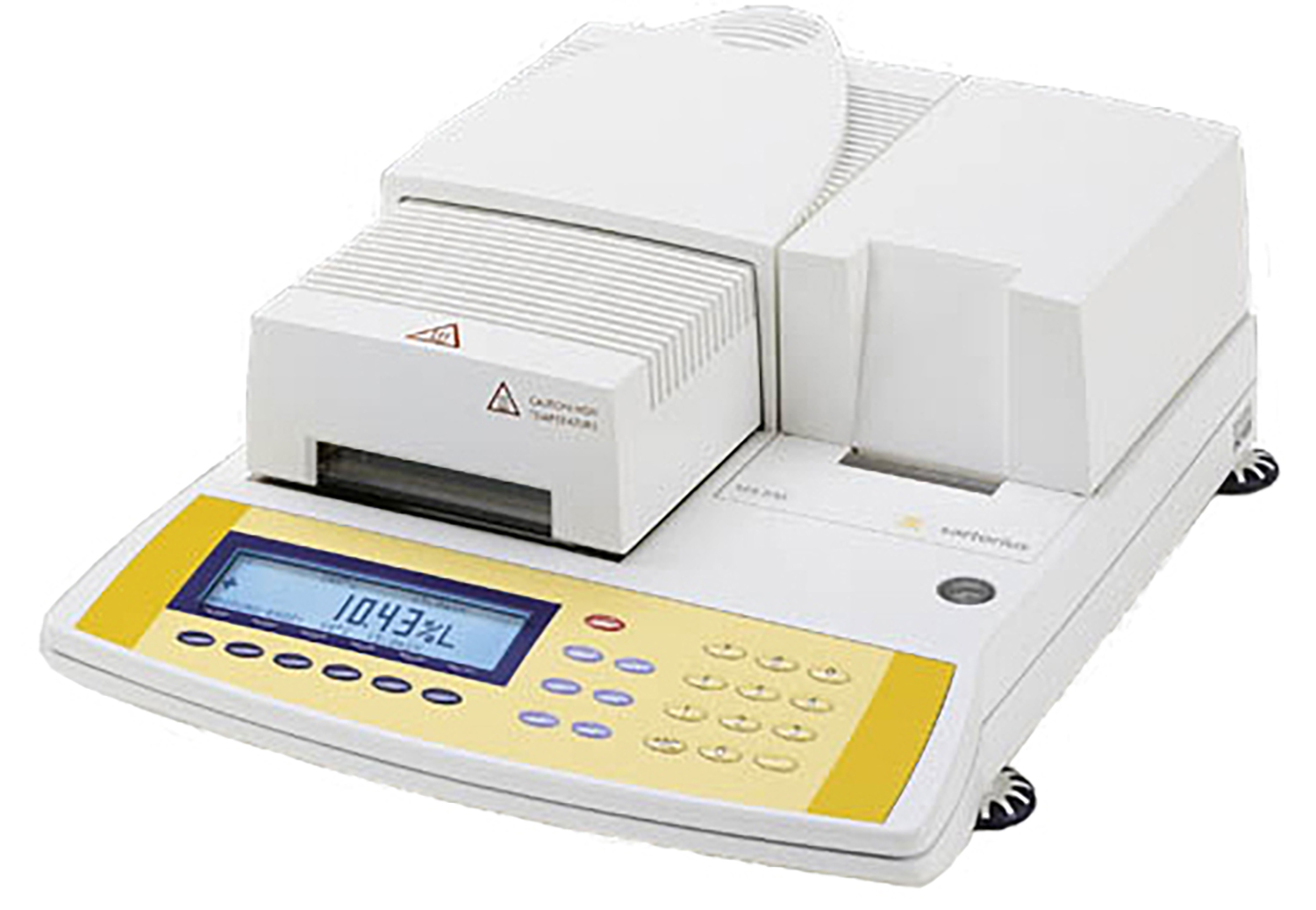

- Model no. H3021-0002

- Tests on raw materials

The tester for determining moisture content is used to quickly and reliably determine the material moisture content of liquid, paste-like and solid substances according to the thermogravimetric method.

Standards

- ISO 585

- EN 12118

- Model no. H3022

- Tests on raw materials

According to the method for the assessment of the degree of pigment and carbon black dispersion in polyolefin pipes, fittings and compounds, a microscope is required to examine the particles and agglomerates in the test sample.

Standards

- ISO 18553

- ASTM D 5596

- Model no. H3023

- Measuring devices

The micrometer (also known as a micrometer gauge) is used to determine thickness.

Standards

- ISO 3126

- Model no. H3024

- Measuring devices

Vernier calipers are the simplest way to measure the ovality of pipes.

Standards

- ISO 3126

- Model no. H3026

- Sample preparation

The walk-in cooling chamber is used to condition specimens to the preset temperature.

Standards

- ISO 3126

- Model no. H3031-0100/0101

- Sample preparation

Standards

- ISO 527

- ISO 6259

- Model no. H3047

- Sample preparation

Standards

- ISO 179

- ISO 180